Welcome to the 10th edition of Trade War. Monday February 10 was the day that business was supposed to resume to normal across China, with people returning to work and companies reopening, including its many export factories. That clearly did not happen.

Overzealous local officials

Even as the central government in Beijing announced the official national reopening, local governments across China ignored the order. In Guangdong province in particular, China’s biggest export manufacturing base, cities from Zhongshan to Foshan instructed factories to wait, usually until March 1 to reopen, as this tweet thread shows.

Fears that factories — and construction sites -- could become a vector for disease transmission are well-founded, given that many workers sit near each other on production lines or work in close proximity on building sites, Wang Kan, professor at the China Institute of Industrial Relations, tells Trade War in a phone interview.

“Back to work”

What would normally be packed subway stations across the country, not surprisingly, did not show a large pickup in use. While many white collar workers tried to do their jobs from home, many other people still had no work to return to. Not just factories but also company offices across the country—also often responding to orders to stay shut from the local governments where they are based—did not reopen either.

“They are afraid”

Most small shops, those that sell fruit, vegetables or daily use goods, and that traditionally have been the lifeblood of China’s cities, have not restarted business; their owners and employees, the bulk of which are migrants and had returned to their homes in the countryside for the Lunar New Year, have now delayed their return to the cities. “They have no desire to come back right now as they are afraid,” Wang Kan told Trade War.

Meanwhile, some businesses that are open are finding novel ways to deliver goods while minimizing close human contact.

Underestimating the damage

As the spread of the coronavirus continues, serious questions are starting to be asked about the longterm viability of centering so much of the world’s key supply chains in China. Already, the trade war tariffs, plus demographic changes that have raised the costs of labor, had multinationals beginning to pick up some of their operations and set up shop elsewhere, often in other parts of Asia including Vietnam, Indonesia, and India.

Author and journalist Michael Schuman warns in a tweet that U.S. investors are “underestimating the damage” the virus will cause, including by hurting corporate profits and cutting off global growth.

A broken supply chain?

China’s still widespread travel bans and transportation restrictions in particular will inflict serious damage on the overall industrial economy, and its lifeblood, China’s until now unparalleled supply chains, says this interesting tweet thread. And damage to supply chains means damage to global trade of course.

Apple as a bellwether for decoupling

And while some production looks set to restart at one key Foxconn facility producing iPhones in Zhengzhou, Apple perhaps more than any company, is being watched to see how it will respond to the virus and deal with its shuttered supplier factories. If it decides to move more rapidly to diversify production to places outside China, it would be seen as a bellwether of decoupling.

“The coronavirus outbreak has given new meaning to something Apple executives have been saying for years: Apple needs another China,” says a report by the Wall Street Journal on February 5.

Disrupts both internal and external trade

Former Pimco CEO Mohamed A. El-Erian sees the coronavirus injecting deep uncertainty into China’s overall economic outlook and for the global economy. That’s because the virus "involves critical interruptions to both demand and supply; it impacts both manufacturing and services; and it disrupts both internal and external trade," he writes in Bloomberg Opinion.

Face mask shortage

It’s also got companies distracted from their main business: As a worldwide shortage of face masks looms, firms in China including electric vehicle and battery maker BYD, SAIC-GM-Wuling, the joint venture for General Motors, and yes, Apple assembler Foxconn, have all started making their own protective gear.

“Foxconn began making masks on Feb. 5 for its 1 million employees, saying daily production is expected to reach 2 million pieces by the end of the month,” Bloomberg News reports on February 9. “While China made more than 5 billion face masks on the mainland last year -- about half the world’s output -- there’s still a shortage as the number of infections soars.”

And drug shortages?

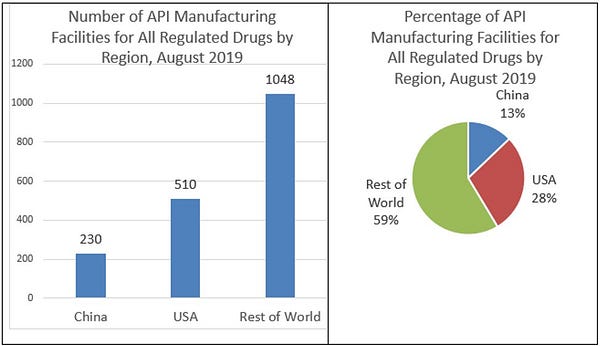

Drug shortages in China and the U.S. are a worry too, warns Scott Gottlieb, MD, a resident fellow at AEI. The two countries dominate global production, making up 41% of drug manufacturing.

German factory orders

Factory orders are falling in Germany, a sign of the deepening global malaise. They fell 8.7% YoY, the most since the beginning of the global financial crisis in September 2009.

Phase One delight?

So what’s going on with the “phase one” trade deal, everybody celebrating that? Not so, apparently. "I'm one of those farmers who is supposed to be delighted with the US-China "Phase One" trade deal. ... Although I'm hopeful that it will give farmers a boost, I'm more than a little worried that it won't," writes Mark Wagoner, who grows alfalfa seed and wheat on his family farm in Washington, in CNN.com.

Meanwhile, the Trump administration is touting its trade successes, with Commerce Secretary Wilbur Ross tweeting that “trade wins for America” are “shrinking the trade deficit and leveling the playing field for U.S. exporters.”

Pain per family

Whether or not that’s true, it isn’t carrying over to the American consumer. Peterson Institute economist Gary Hufbauer predicts that the average U.S. household still will face a net loss from tariffs next year, and a report from the Congressional Budget Office puts the pain per family at $1,277.

Notable/In Depth

Lots of interesting charts on the coronavirus impact on markets and economies in this Reuters report.

A good podcast on the coronavirus, trade, and decoupling from China business maven James McGregor.

And here’s an interesting piece from the Wall Street Journal that argues that Vietnam and Mexico have been the true winners of the U.S.-China trade war.